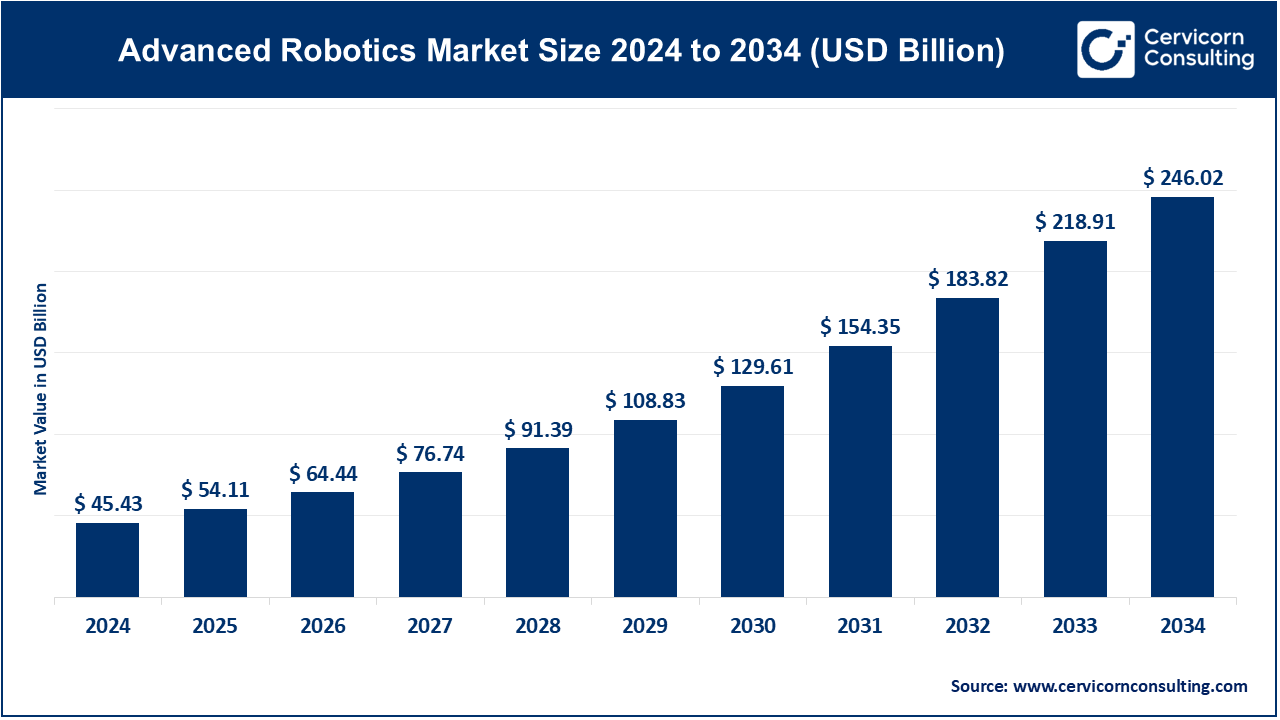

The global advanced robotics market size was accounted for USD 45.43 billion in 2024 and is estimated to reach around USD 246.02 billion by 2034, growing at a compound annual growth rate (CAGR) of 19.09% from 2025 to 2034.

The advanced robotics market has seen remarkable growth in recent years, driven by advancements in artificial intelligence, machine learning, and automation. As industries across the globe aim to enhance productivity and efficiency, robots are becoming more integral to various sectors. The market for advanced robotics is expected to continue expanding as businesses adopt automation solutions to address labor shortages, reduce operational costs, and improve safety. In particular, the manufacturing sector has been a significant contributor to this growth, as companies embrace robotics for tasks such as assembly, inspection, and material handling. By the end of 2023, there were approximately 4.28 million operational industrial robots worldwide, marking a 10% increase from the previous year. In addition to manufacturing, the healthcare sector has also shown significant interest in advanced robotics. Surgical robots, for instance, offer enhanced precision and reduce the risk of human error in procedures. The growing demand for automation in logistics, healthcare, and agriculture is propelling the market forward.

Advanced robotics refers to the design, development, and application of robots that are capable of performing tasks autonomously or with minimal human intervention. These robots often utilize advanced technologies such as artificial intelligence (AI), machine learning, sensors, and advanced materials. They can perform complex tasks with precision and are used in various industries like manufacturing, healthcare, logistics, and agriculture. Unlike traditional robots, advanced robots are capable of adapting to changing environments, learning from their experiences, and making decisions based on data. Examples of advanced robotics include surgical robots, autonomous drones, and collaborative robots (cobots) that work alongside humans.

Report Scope

| Area of Focus | Details |

| Market Size in 2025 | USD 54.11 Billion |

| Market Size by 2034 | USD 246.02 Billion |

| Market Growth Rate | CAGR of 19.09% from 2025 to 2034 |

| Largest Market | North America |

| Fastest Growing Market | Asia Pacific |

| Segment Coverage | By Component, Service, Application, End-Users and Regions |

Increased Funding and Investment

Workplace Flexibility and Adaptability

Economic Volatility

Regulatory Challenges

Emerging Technologies

Growing Awareness and Education

Supply Chain Disruptions

Skilled Labor Shortages

Pre-Fabrication Services: The demand for pre-fabricated robotics components is on the rise due to their efficiency and reduced assembly time. Technological advancements now enable the production of high-quality, custom-designed parts that can meet specific project requirements, enhancing both speed and accuracy in robotic deployments. This service type offers significant benefits, including customization and high quality, which streamline the construction and implementation processes in various industries. As a result, there is a growing adoption of pre-fabrication services in manufacturing sectors seeking time and cost efficiency.

Installation Services: Professional installation services are critical in the advanced robotics market, ensuring that systems are set up correctly and safely. This promotes both durability and operational efficiency. Whether for new deployments or system upgrades, proper installation is essential to maximize the functionality and lifespan of robotic systems. The increasing demand for quick and cost-effective solutions in industries underscores the importance of skilled installation services, which play a pivotal role in the successful integration of advanced robotics into existing operations.

Regular Maintenance: Regular maintenance services are vital for ensuring the longevity and optimal performance of robotic systems. These services typically include inspections, cleaning, and minor repairs, which help prevent significant issues and maintain the operational quality of the robots. As more businesses recognize the importance of uninterrupted operations, the demand for regular maintenance is rising. This proactive approach to upkeep ensures that robotic systems continue to function efficiently, minimizing downtime and extending their useful life.

Repair Services: Repair services are essential for addressing damages to robotic systems caused by accidents, environmental factors, or aging. Skilled professionals provide targeted repairs to restore the integrity and functionality of these systems, ensuring they meet performance and safety standards. As the number of robotic installations increases, so does the need for reliable repair services. These services are crucial for maintaining the operational capability of robots, helping businesses avoid costly disruptions and prolonging the lifespan of their investments.

Design Services: Design services play a crucial role in creating customized robotic solutions tailored to meet specific project needs. Engineers and designers collaborate closely with clients to develop innovative and functional designs that enhance efficiency and usability. The flexibility offered by advanced design services allows for the creation of tailored robotic systems that can address unique operational challenges. This customization is increasingly in demand across various industries, as businesses seek to leverage robotics to improve productivity and solve specific problems.

Consulting Services: Consulting services provide expert guidance on the selection, installation, and maintenance of robotic systems. These services help clients make informed decisions, ensuring optimal performance and compliance with industry standards. Consultants offer valuable insights into the best practices for integrating robotics into business operations, enhancing the overall effectiveness of these systems. As the complexity of robotic technologies grows, so does the reliance on consulting services to navigate these advancements and maximize their benefits.

Manufacturing Automation: Advanced robotics are widely utilized in manufacturing for tasks such as assembly, welding, and quality control. These robots significantly improve efficiency and precision, driving productivity in industrial settings. The adoption of robotics in manufacturing is growing, particularly in industries like automotive, electronics, and food processing, where high accuracy and speed are crucial. By automating repetitive and complex tasks, robots help manufacturers reduce costs and increase output, making them indispensable in modern production processes.

Healthcare Robotics: In healthcare, robots assist in surgeries, rehabilitation, and patient care, enhancing precision and reducing human error. Telepresence robots also improve accessibility to medical services, allowing for remote consultations and treatments. The integration of robotics in healthcare is expanding, driven by the need for advanced medical solutions that improve patient outcomes and operational efficiency. As a result, robotic systems are becoming a standard feature in hospitals and clinics, revolutionizing medical procedures and patient care.

Logistics and Warehousing: Robots optimize supply chain operations, including inventory management, sorting, and delivery. They enhance efficiency and reduce labor costs in warehouses and distribution centers. The growth of e-commerce has significantly increased the demand for logistics and warehousing robots, which help manage the high volume of goods and ensure timely deliveries. By automating critical processes, these robots enable businesses to streamline their operations, improve accuracy, and meet the fast-paced demands of modern logistics.

Agricultural Robotics: Agricultural robots assist in tasks such as planting, harvesting, and crop monitoring, improving productivity and sustainability in farming operations. These robots use advanced technologies to perform precise and efficient agricultural tasks, reducing the need for manual labor and minimizing waste. The adoption of robotics in agriculture is growing, particularly in precision farming and organic farming, where accuracy and environmental sustainability are paramount. By enhancing crop production and farm management, agricultural robots contribute to a more efficient and sustainable food supply chain.

Service and Hospitality: In the service and hospitality sectors, robots perform tasks such as customer service, cleaning, and delivery, enhancing the customer experience and operational efficiency. These robots are increasingly used in hotels, restaurants, and retail environments to provide seamless and efficient services. By automating routine tasks, service robots allow human staff to focus on more complex and personalized customer interactions, improving overall service quality. The growing deployment of robotics in hospitality reflects the industry's commitment to innovation and customer satisfaction.

Defense and Security: Defense robots are used for surveillance, reconnaissance, and combat operations, enhancing safety and operational effectiveness in military and security applications. These robots can perform hazardous tasks, reducing the risk to human soldiers and improving mission outcomes. The investment in defense robotics is increasing, driven by the need for advanced technological solutions in national security. Unmanned systems and autonomous vehicles are becoming integral components of modern defense strategies, providing enhanced capabilities and strategic advantages

Large-Scale Enterprises: Large enterprises, such as multinational manufacturers and logistics companies, invest heavily in advanced robotics to boost efficiency and maintain a competitive edge. These companies seek scalable and innovative solutions that can enhance their operational capabilities and drive growth. By integrating advanced robotics, large-scale enterprises can streamline their processes, reduce costs, and improve overall productivity, ensuring they stay ahead in the competitive global market.

SMEs (Small and Medium-Sized Enterprises): SMEs benefit from the versatility and cost-effectiveness of advanced robotics, enabling them to compete with larger firms by improving productivity and reducing operational costs. These smaller businesses can leverage robotics to automate repetitive tasks, optimize workflows, and enhance product quality. The affordability and technological advancements in robotics make them an attractive option for SMEs looking to scale their operations and improve efficiency without significant financial outlays.

Retail and Hospitality Companies: Retailers and hospitality businesses deploy robots to improve customer service, manage inventory, and streamline operations, enhancing the overall customer experience. These robots perform tasks such as restocking shelves, guiding customers, and delivering room service, allowing human staff to focus on more complex interactions. The flexibility and efficiency offered by robotics enable retail and hospitality companies to adapt to changing customer needs and industry trends, ensuring high levels of service and operational efficiency.

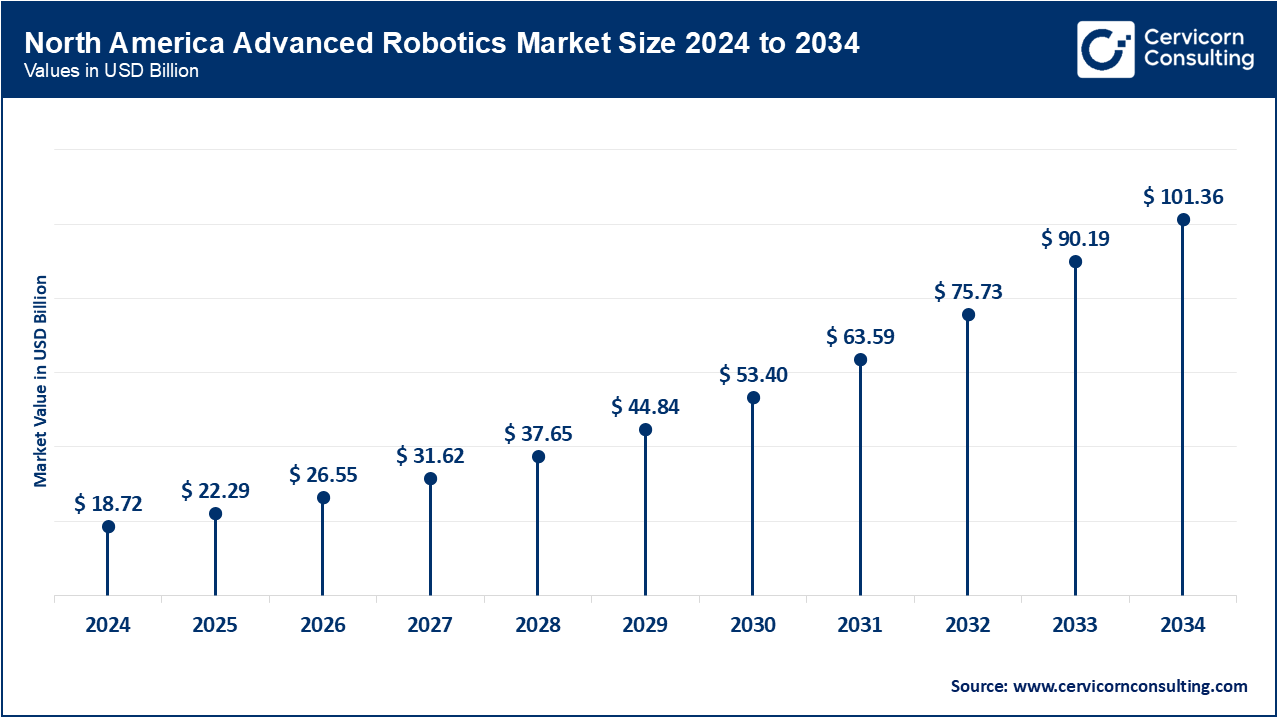

The North America market size is expected to reach around USD 101.36 billion by 2034 increasing from USD 18.72 billion in 2024 with a CAGR of 18.8%. North America emerges as the largest Advanced Robotics Market owing to its developed technology industry and stringent need for sophisticated automation systems. The U.S market size is estimated to reach around USD 81.09 billion by 2034 increasing from USD 14.97 billion in 2024 with a CAGR of 18.9%. The U. S. and Canada are seen being the most advanced countries in integrating modern robotics in production, hospitals, and warehouses. Innovative products, changing consumer preferences and legal requirements to improve research & development push the growth of the market along with the hike in productivity and operating performance. Also, the concentration on applying AI and machine learning to robotic systems to meet the necessitate smart as well as flexible fixings is in line with emerging trends in the region.

The Asia Pacific market size is calculated at USD 9.59 billion in 2024 and is projected to grow around USD 51.91 billion by 2034 with a CAGR of 19.50%. Currently, the Asia-Pacific region is recording the highest growth in Advanced Robotics Market due to growing industrialization, higher disposable income, and increasing technology. Many capable nations including the Chinese, Japanese, and Koreans among others have adopted the more technologically driven robots in manufacturing, electronics, auto industries among others. There is an evident demand for both conventional and innovative robotics technologies with substantial The government support and funding for smart manufacturing and environment-friendly production processes. The latter is prompted by the regions’ goal to become a global hub for robotics, which dictate steady market growth.

The Europe market size is measured at USD 13.72 billion in 2024 and is expected to grow around USD 74.3 billion by 2034 with a CAGR of 18.00%. Through detailed research, this paper finds that the advanced robotics market in Europe has been fueled by the integration of manufacturing systems and the push for sustainability. The region enjoys growth based on friendly government policies, increase calls for Industry 4. 0 initiatives, and increase in awareness of the public towards automation. European countries such as Germany, United Kingdom and France have immensely embraced the use of robotics in industries, healthcare and as service delivery. Focus on lowering the costs per labor, increasing accuracy, and incorporating robotics with the current industrial structures also foster the market expansion.

The LAMEA market size is forecasted to reach around USD 18.45 billion by 2034 from USD 3.41 billion in 2024 with a CAGR of 17.30%. Currently the LAMEA (Latin America, Middle East, and Africa) advanced robotics market is getting developed due to increase in awareness levels and betterment of industrial structure. In Latin America there it becomes a higher pressure on the optimization of production and implementation of automation tools. The Middle East enjoys tremendous inflow of capital on modern day robotics especially in the sectors of oil and gas, construction and health care industry. Despite the limitations to resources, Africa continues improving its use of technology, meaning Internationals collaborations and funding possibilities for advanced robotics applications.

Among the new players, Blue River Technology leverages advanced machine learning and computer vision to provide innovative agricultural robotics solutions, enhancing precision and environmental impact. Clearpath Robotics focuses on developing autonomous mobile robots, combining advanced navigation technologies with high performance for various industrial applications. Dominating players like ABB Ltd. drive growth through their extensive product lines and recent innovations, including collaborative robots for manufacturing. FANUC Corporation integrates advanced AI technologies with its wide range of robotic systems, facilitating comprehensive automation solutions. Innovations and collaborations, such as ABB’s new product launches and FANUC’s strategic partnerships, underscore their leadership in the evolving Advanced Robotics Market.

John Ha, CEO of Bear Robotics:

" Just as Android revolutionized the smartphone era, standardized open platforms are essential for the activation of the robot market."

Robert Playter, CEO of Boston Dynamics:

" Everybody will buy one robot—we learned that with Spot. But they won’t start by buying fleets, and you don’t have a business until you can sell multiple robots to the same customer."

Market Segmentation

By Component

By Service Type

By Application Type

By End-Users

By Regions

Chapter 1 Market Introduction and Overview

1.1 Market Definition and Scope

1.1.1 Overview of Advanced Robotics

1.1.2 Scope of the Study

1.1.3 Research Timeframe

1.2 Research Methodology and Approach

1.2.1 Methodology Overview

1.2.2 Data Sources and Validation

1.2.3 Key Assumptions and Limitations

Chapter 2 Executive Summary

2.1 Market Highlights and Snapshot

2.2 Key Insights by Segments

2.2.1 By Component Overview

2.2.2 By Service Type Overview

2.2.3 By Application Type Overview

2.2.4 By End-Users Overview

2.3 Competitive Overview

Chapter 3 Global Impact Analysis

3.1 COVID 19 Impact on Advanced Robotics Market

3.1.1 COVID-19 Landscape: Pre and Post COVID Analysis

3.1.2 COVID 19 Impact: Global Major Government Policy

3.1.3 Market Trends and Opportunities in the COVID-19 Landscape

3.2 Russia-Ukraine Conflict: Global Market Implications

3.3 Regulatory and Policy Changes Impacting Global Markets

Chapter 4 Market Dynamics and Trends

4.1 Market Dynamics

4.1.1 Market Drivers

4.1.1.1 Increased Funding and Investment

4.1.1.2 Workplace Flexibility and Adaptability

4.1.2 Market Restraints

4.1.2.1 Economic Volatility

4.1.2.2 Regulatory Challenges

4.1.3 Market Opportunity

4.1.3.1 Emerging Technologies

4.1.3.2 Growing Awareness and Education

4.1.4 Market Challenges

4.1.4.1 Supply Chain Disruptions

4.1.4.2 Skilled Labor Shortages

4.2 Market Trends

Chapter 5 Premium Insights and Analysis

5.1 Global Advanced Robotics Market Dynamics, Impact Analysis

5.2 Porter’s Five Forces Analysis

5.2.1 Bargaining Power of Suppliers

5.2.2 Bargaining Power of Buyers

5.2.3 Threat of Substitute Products

5.2.4 Rivalry among Existing Firms

5.2.5 Threat of New Entrants

5.3 PESTEL Analysis

5.4 Value Chain Analysis

5.5 Product Pricing Analysis

5.6 Vendor Landscape

5.6.1 List of Buyers

5.6.2 List of Suppliers

Chapter 6 Advanced Robotics Market, By Component

6.1 Global Advanced Robotics Market Snapshot, By Component

6.1.1 Market Revenue (($Billion) and Growth Rate (%), 2022-2034

6.1.1.1 Hardware

6.1.1.2 Software

6.1.1.3 Service

Chapter 7 Advanced Robotics Market, By Service Type

7.1 Global Advanced Robotics Market Snapshot, By Service Type

7.1.1 Market Revenue (($Billion) and Growth Rate (%), 2022-2034

7.1.1.1 Prefabrication Services

7.1.1.2 Installation Services

7.1.1.3 Regular Maintenance

7.1.1.4 Repair Services

7.1.1.5 Design Services

7.1.1.6 Consulting Services

Chapter 8 Advanced Robotics Market, By Application Type

8.1 Global Advanced Robotics Market Snapshot, By Application Type

8.1.1 Market Revenue (($Billion) and Growth Rate (%), 2022-2034

8.1.1.1 Manufacturing Automation

8.1.1.2 Healthcare Robotics

8.1.1.3 Logistics and Warehousing

8.1.1.4 Agriculture Robotics

8.1.1.5 Service and Hospitality

8.1.1.6 Defense and Security

8.1.1.7 Collaborative Robots

8.1.1.8 Others

Chapter 9 Advanced Robotics Market, By End-Users

9.1 Global Advanced Robotics Market Snapshot, By End-Users

9.1.1 Market Revenue (($Billion) and Growth Rate (%), 2022-2034

9.1.1.1 Large-Scale Enterprises

9.1.1.2 SMEs (Small and Medium-Sized Enterprises)

9.1.1.3 Retail and Hospitality Companies

Chapter 10 Advanced Robotics Market, By Region

10.1 Overview

10.2 Advanced Robotics Market Revenue Share, By Region 2024 (%)

10.3 Global Advanced Robotics Market, By Region

10.3.1 Market Size and Forecast

10.4 North America

10.4.1 North America Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.4.2 Market Size and Forecast

10.4.3 North America Advanced Robotics Market, By Country

10.4.4 U.S.

10.4.4.1 U.S. Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.4.4.2 Market Size and Forecast

10.4.4.3 U.S. Market Segmental Analysis

10.4.5 Canada

10.4.5.1 Canada Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.4.5.2 Market Size and Forecast

10.4.5.3 Canada Market Segmental Analysis

10.4.6 Mexico

10.4.6.1 Mexico Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.4.6.2 Market Size and Forecast

10.4.6.3 Mexico Market Segmental Analysis

10.5 Europe

10.5.1 Europe Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.5.2 Market Size and Forecast

10.5.3 Europe Advanced Robotics Market, By Country

10.5.4 UK

10.5.4.1 UK Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.5.4.2 Market Size and Forecast

10.5.4.3 UK Market Segmental Analysis

10.5.5 France

10.5.5.1 France Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.5.5.2 Market Size and Forecast

10.5.5.3 France Market Segmental Analysis

10.5.6 Germany

10.5.6.1 Germany Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.5.6.2 Market Size and Forecast

10.5.6.3 Germany Market Segmental Analysis

10.5.7 Rest of Europe

10.5.7.1 Rest of Europe Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.5.7.2 Market Size and Forecast

10.5.7.3 Rest of Europe Market Segmental Analysis

10.6 Asia Pacific

10.6.1 Asia Pacific Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.6.2 Market Size and Forecast

10.6.3 Asia Pacific Advanced Robotics Market, By Country

10.6.4 China

10.6.4.1 China Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.6.4.2 Market Size and Forecast

10.6.4.3 China Market Segmental Analysis

10.6.5 Japan

10.6.5.1 Japan Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.6.5.2 Market Size and Forecast

10.6.5.3 Japan Market Segmental Analysis

10.6.6 India

10.6.6.1 India Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.6.6.2 Market Size and Forecast

10.6.6.3 India Market Segmental Analysis

10.6.7 Australia

10.6.7.1 Australia Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.6.7.2 Market Size and Forecast

10.6.7.3 Australia Market Segmental Analysis

10.6.8 Rest of Asia Pacific

10.6.8.1 Rest of Asia Pacific Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.6.8.2 Market Size and Forecast

10.6.8.3 Rest of Asia Pacific Market Segmental Analysis

10.7 LAMEA

10.7.1 LAMEA Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.7.2 Market Size and Forecast

10.7.3 LAMEA Advanced Robotics Market, By Country

10.7.4 GCC

10.7.4.1 GCC Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.7.4.2 Market Size and Forecast

10.7.4.3 GCC Market Segmental Analysis

10.7.5 Africa

10.7.5.1 Africa Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.7.5.2 Market Size and Forecast

10.7.5.3 Africa Market Segmental Analysis

10.7.6 Brazil

10.7.6.1 Brazil Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.7.6.2 Market Size and Forecast

10.7.6.3 Brazil Market Segmental Analysis

10.7.7 Rest of LAMEA

10.7.7.1 Rest of LAMEA Advanced Robotics Market Revenue, 2022-2034 ($Billion)

10.7.7.2 Market Size and Forecast

10.7.7.3 Rest of LAMEA Market Segmental Analysis

Chapter 11 Competitive Landscape

11.1 Competitor Strategic Analysis

11.1.1 Top Player Positioning/Market Share Analysis

11.1.2 Top Winning Strategies, By Company, 2022-2024

11.1.3 Competitive Analysis By Revenue, 2022-2024

11.2 Recent Developments by the Market Contributors (2024)

Chapter 12 Company Profiles

12.1 ABB

12.1.1 Company Snapshot

12.1.2 Company and Business Overview

12.1.3 Financial KPIs

12.1.4 Product/Service Portfolio

12.1.5 Strategic Growth

12.1.6 Global Footprints

12.1.7 Recent Development

12.1.8 SWOT Analysis

12.2 Boston Dynamics

12.3 FANUC

12.4 KUKA

12.5 Yaskawa Electric Corporation

12.6 iRobot

12.7 Intuitive Surgical

12.8 Universal Robots

12.9 SoftBank Robotics

12.10 Teradyne