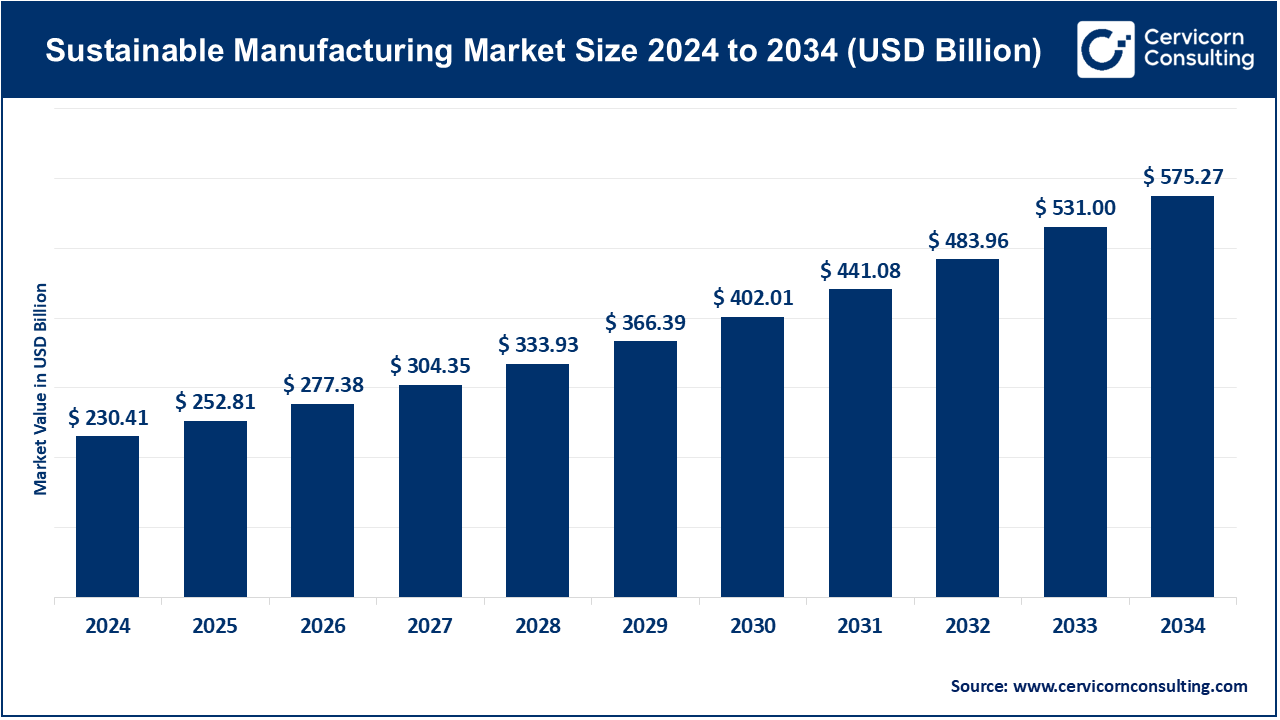

The global sustainable manufacturing market size was valued at USD 230.41 billion in 2024 and is expected to be worth around USD 575.27 billion by 2034, growing at a compound annual growth rate (CAGR) of 9.58% from 2025 to 2034.

The sustainable manufacturing market has been experiencing steady growth as industries face increasing pressure to adopt environmentally friendly practices. As global awareness about climate change rises, governments, businesses, and consumers are emphasizing the need for greener manufacturing processes. Technological advancements in energy-efficient production, waste management, and renewable energy sources are driving this trend forward. The adoption of sustainability is seen not only as a regulatory necessity but also as a competitive advantage, enabling companies to attract environmentally conscious consumers and investors. The market is also expanding due to growing investments in research and development for sustainable technologies. Companies across sectors like automotive, electronics, and consumer goods are increasingly focused on reducing their ecological footprint. In the United States, manufacturers are prioritizing sustainability, with 79% focusing on manufacturing and production, 69% on supply chain, and 67% on product design and development. Energy efficiency and the transition to renewable energy sources are top priorities, aligning with net-zero emissions goals. With the rising demand for eco-friendly products and the shift towards circular economy models, sustainable manufacturing is anticipated to continue its upward trajectory.

Sustainable manufacturing is a process of producing goods in a way that minimizes environmental impact, conserves resources, and promotes social and economic well-being. This approach focuses on reducing energy consumption, using renewable materials, minimizing waste, and ensuring ethical labor practices throughout the production process. By integrating eco-friendly technologies and efficient resource use, manufacturers aim to reduce their carbon footprint and operate more responsibly. Sustainability in manufacturing is not just about improving environmental performance but also about creating long-term value for both businesses and society.

Report Scope

| Area of Focus | Details |

| Market Size in 2025 | USD 252.81 Billion |

| Projected Market Size (2034) | USD 575.27 Billion |

| Growth Rate from 2025 to 2034 | 9.58% |

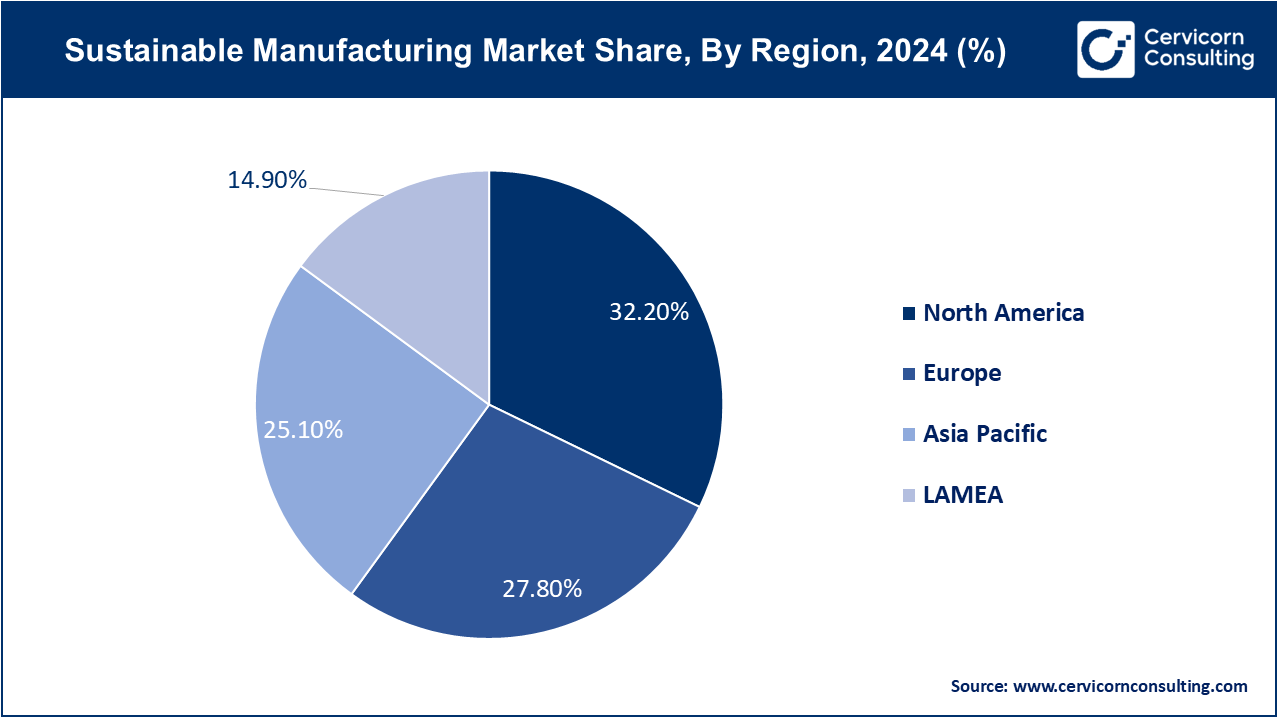

| Dominant Region | North America |

| Expanding Region | Asia Pacific |

| Key Segments | Product, Offering, Technology, Application, End User, Region |

| Key Companies | Siemens AG, General Electric, Schneider Electric, Honeywell International Inc., Johnson Controls International, ABB Ltd., 3M Company, Panasonic Corporation, Emerson Electric Co., Rockwell Automation, Mitsubishi Electric Corporation, Caterpillar Inc., Tesla Inc., Danfoss Group, Eaton Corporation |

Increased Regulatory Pressure

Advancements in Sustainable Technologies

High Transition Costs

Skill Gaps and Training Requirements

Expansion into Emerging Markets

Technological Collaboration and Integration

Supply Chain Complexities

Public and Stakeholder Perception

The sustainable manufacturing market is segmented into offering, product type, technology, application, end-user and region. Based on offering, the market is classified into recycled lithium ion battery, water reuse and recycling, recycled plastics, green hydrogen, recycled steel, recycled aluminium, recycled carbon fibre, bioplastics & biopolymers, natural fibre composites. Based on product type, the market is classified into energy-efficient equipment, recycled materials, biodegradable products, and low-emission products. Based on technology, the market is classified into advanced material technologies, energy management systems, pollution control technologies, automation and robotics. Based on application, the market is classified into resource optimization, waste management, emissions reduction, and product lifecycle management. Based on end-user, the market is classified into industrial, commercial, residential, government and public sector.

Resource Optimization: This application is centered on improving efficiency in the utilization of input resources especially materials and energy and hence minimizing costs of production. Some of the categories of techniques include lean manufacturing, layout and workflow, and planning systems.

Waste Management: Stresses the minimization of the generation of wastes and encourages the recycling and reusing of the wastes generated during the manufacturing process. This application can be very useful in the conservation of natural resources as well as the prevention of an act that would pollute the environment.

Emissions Reduction: Accomplishes the use of fresh approaches of manufacturing and technology that help in reducing pollution and emission of greenhouse gasses. This all important in fulfilling the global environment requirements and enhancing the quality of air.

Product Lifecycle Management: Improves sustainability of products during conception, fabrication, utilization, and finally disposal. It aims at the concepts of designing durable, repairable, upgradable, and recyclable products which further reduces the commercial lifecycle of products.

Energy-Efficient Equipment: Assist sub that incorporates machinery and tools in the product design to operate using the lowest amount of energy as possible. These products are a necessity when it comes to cutting down operating expenses and minimizing Carbon footprint of manufacturing companies.

Recycled Materials: Circular economy sustainable development products embrace those manufactured from recycled material since they cut Virgil material demand and waste.

Biodegradable Products: These are products that are manufactured to disintegrate after sometime thus sparing the environment from more pollution.

Low-Emission Products: Products made through eco-friendly processes with the objective of mitigating climatic changes and improvised air quality.

Advanced Material Technologies: This can mean installing new materials that are far more eco-friendly like bioplastics or even composites that take less energy to manufacture and which are completely recyclable.

Energy Management Systems: Smart devices such as sensors and controls for process optimization and efficiency, Improve monitoring of energy use in the manufacturing processes and efficient energy-using equipment.

Pollution Control Technologies: Products that enable the controlling of the quantity and quality of emissions and effluents resulting from manufacturing processes, with sophisticated filters and scrubbers as examples.

Automation and Robotics: Hire an automated system to manage production lines, and minimize and or eliminate human intervention to lower the cost and waste of resources. These technologies are crucial in attaining high tolerance and low scrap rate to the production process.

Industrial: Refers to manufacturing industries that integrate environmental consciousness in the production process in order to reduce on the effects of their activities on the environment but not on efficiency and output.

Commercial: Larger organisations in diverse sectors integrating sustainability within their manufacturing processes to accomplish legal expectations and market trends towards environmentally friendly products.

Residential: Specializes in manufacturers of domestic products that use eco-friendly material and process to capture the market of the green consumers.

Government and Public Sector: Refers to such publicly-funded projects that call for the use of environmentally harvested resources and processes, due to governmental rules and green initiatives.

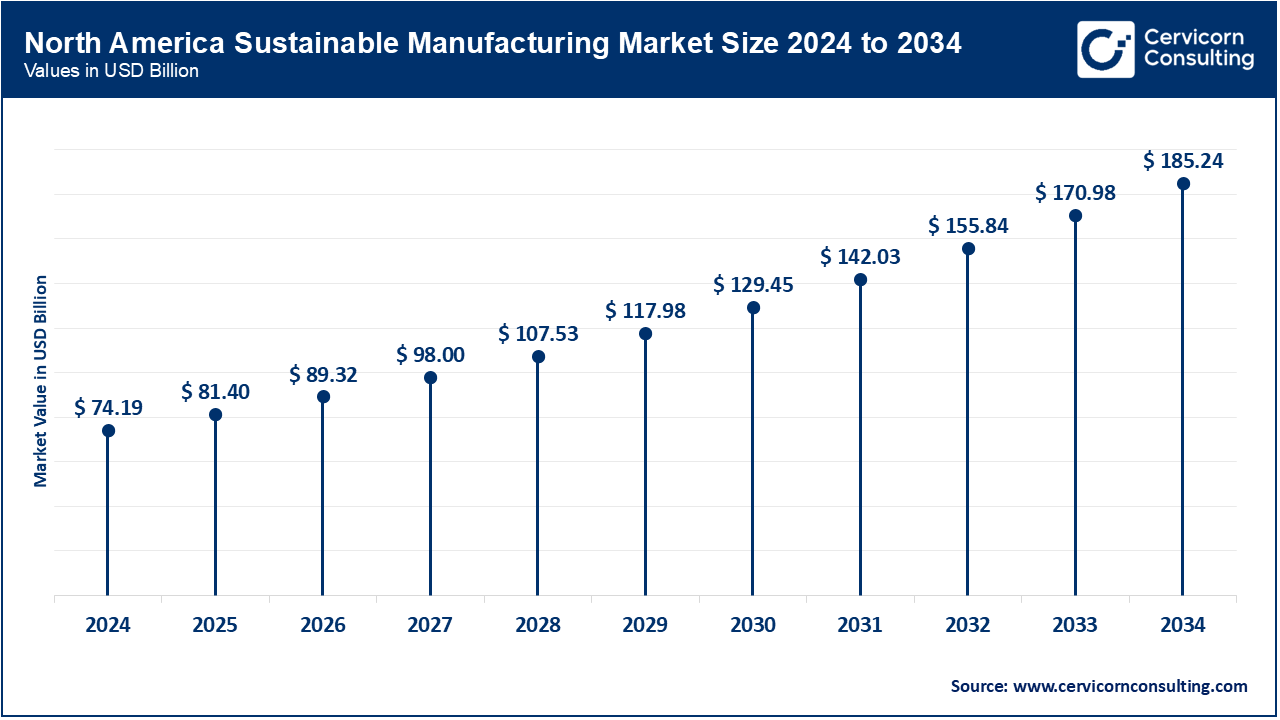

The North America sustainable manufacturing market size was estimated at USD 74.19 billion in 2024 and is expected to reach around USD 185.24 billion by 2034. North America holds the largest share in the market due to strong industrial norms, proper and active legislations on environmental issues and huge investment on green technology. The United States is leading with its large manufacturing industry stepping up its green measures to lower the environmental footprint and improve performance. It is is up to date with research and development in environmentally friendly process, and as such hosts cutting edge solutions sustainable processes manufacturing. Canada is also expected to rise at a substantial growth rate, especially in eliminating the sustainability crisis in the manufacturing sector to boost the demand for the market.

The Europe sustainable manufacturing market size was accounted for USD 64.05 billion in 2024 and is projected to hit around USD 159.92 billion by 2034. As such, Europe witnesses a higher growth in the market as compared to the global average due to massive support from the government and industries. Germany, France and the United Kingdom among others can be aptly classified as leaders in manufacturing markets relying and investing on renewable energy and sustainability. Latest agenda to decrease carbon footprints and improve efficiency of manufacturing which are the part of organizational development strategies is supported by the European Union by carrying forward similar objectives. Like most other European countries manufacturing markets, green manufacturing is expected to have steady growth, fueled by regulations as well as the need to conform to environmental standards by European countries.

The Asia-Pacific sustainable manufacturing market size was estimated at USD 57.83 billion in 2024 and is predicted to surpass around USD 144.39 billion by 2034. The Asia-Pacific region is growing at a very fast pace owing to enhanced level of urbanization, improved consumer contends and level of technology innovation. China, Japan and South Korean countries are examples of countries that are proactively investing in sustainable manufacturing with an aim of solving environmental problems and increasing competitiveness. Here are utilizing government assistance and private funding to advance and introduce sustainable technologies in production especially in eve electronics and automotive industries.

The LAMEA sustainable manufacturing market size was valued at USD 34.33 billion in 2024 and is anticipated to reach around USD 85.71 billion by 2034. Even though the market is still in its development phase, the market in context of LAMEA has high growth potential in those regions which have high level of urbanization and industrialization. In Latin America itself, nations such as Brazil are considering sustainable manufacture in order to address issues to do with disposal of waste and consumption of energy within the manufacturing process. The Middle East and the neighbouring countries of the region especially the UAE are keen on adopting green building technologies and sustainable industrial systems to diversify its economy. Africa as a region is still struggling with infrastructure and regulation but there is relatively slow progress being witnessed through international partnerships and by constant investment in improved and sustainable frameworks, especially in the regions of the manufacturing clusters around these cities.

Among the new entrants in the Sustainable Manufacturing Market, one can note that Tesla Inc has been manufacturing electric cars accompanied by home batteries that together will provide energy solutions to free the world from fossil fuel. Besides, Beyond Meat has taken its niche in the development of environmentally friendly food production through the production of plant-based meats to replace real meat to eliminate the effects of livestock production on the environment. On the opposite side, numerous giants, such as Siemens AG with rich experience in industrial automation, establish a profound foundation for the sustainable manufacturing sector incorporating collaborative complete practices of energy-efficient technologies and wise manufacturing solutions.

Schneider Electric uses its worldwide networks to advance sustainable projects on power and automation, and Unilever does the same on sustainability in its uses of products’ materials, production, and manufacturing. These further fuel the progression of the industry, now experiencing organic innovation in the form of huge new market entrants such as Tesla that partner with utility giants such as Siemens – a battleground of both competition and collaboration in the path to sustainable manufacturing. These efforts do a great job of showing how new players and traditional firms currently play in the rapidly shifting Sustainable Manufacturing Market.

CEO Statements

Jim Fitterling, CEO of Dow Inc.

" Sustainable manufacturing is the key to building a cleaner, greener future. At Dow, we are dedicated to reducing our carbon footprint by innovating materials and processes that drive efficiency and sustainability across industries."

Ilham Kadri, CEO of Solvay

" At Solvay, we believe that sustainability is not just a trend, but a necessity. We are committed to creating breakthrough solutions that empower industries to adopt more sustainable manufacturing practices, reducing environmental impact while enhancing economic growth."

Andreas Fibig, Chairman and CEO of International Flavors & Fragrances (IFF)

" Sustainable manufacturing is at the core of our operations. We are continually investing in green technologies, renewable materials, and circular processes to minimize our environmental impact and set a new standard for responsible production."

Dolf van den Brink, CEO of Heineken

" At Heineken, we see sustainable manufacturing as a vital part of our business strategy. By optimizing our energy use, reducing water consumption, and minimizing waste in our breweries, we are working towards a future where quality products are produced with a minimal environmental footprint."

Some of the major driving factors for change in the sustainable manufacturing industry are based on the initiatives made by the key players for sustainable manufacturing that relates to strategies related to energy technology, waste management, and utilization of green resources. Such companies are pushing change by incorporating sustainable ideas like, automation systems, solar and wind power systems, and resource efficiency into their production facilities. Some current trends in the sustainable manufacturing industry include:

Thus, these innovation displays vast growth in the sustainable manufacturing sector with large-scale investment, innovative partnerships, and emerging green technologies. Leaders are paying attention to the use of renewable energy, minimization of waste, and use of energy-efficient systems for green manufacturing. Also, the implementation of circular economy strategies, smart production, and efficiency of resources are aiding in enhancing operational efficiency. These innovations seek to optimize industrial operations and create environmentally friendly production processes while improving productivity and future returns in different industries.

Market Segmentation

By Offering

By Product Type

By Technology

By Application

By End-User

By Regions